TECHNICAL DATA

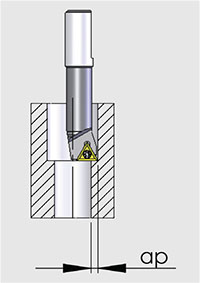

| Meterial | Cutting Speed | Feed (according To Insert Radius) =fn(mm/rotation) | ap=0.1 - 0.3 | ||

|---|---|---|---|---|---|

| R=0.2 | R=0.4 | R=0.8 | |||

| Non-alloyed steel | 150-250 | 0,04-0,08 | 0,07-0,1 | 0,08-0,15 |  |

| Alloyed steel | 100-200 | 0,04-0,08 | 0,07-0,1 | 0,08-0,15 | |

| Stainless | 100-150 | 0,04-0,08 | 0,1-0,15 | 0,1-0,15 | |

| Cast | 90-140 | 0,05-0,08 | 0,08-0,15 | 0,08-0,15 | |

| Aluminum | 200-300 | 0,04-0,08 | 0,05-0,7 | 0,08-0,2 | |

| Heat-resistant steel | 80-120 | 0,03-0,08 | 0,04-0,05 | 0,05-0,07 | |

NOTE 1 : For the calculations giving a value greater than 6000rpm as aresult of the above rotation calculation (n), n=6000 rpm is based.

NOTE 2 : The processing speed should be reduced by 20% and 40%, respectively, if processing depth increases up to four times and 6-7times of processing diameter.

| VC : Cutting Speed D : Processing diameter n : Rotation Vf : Cutting feed fn : (mm/rotaion) π : 3,14 | Vc = π.D.n/1000 n =Vc.1000/ π.D Vf = n.fn |

|

|---|---|---|

| (L/D > 4) -> Vc= Vcx0.8 (L/D > 6) -> Vc= Vcx0.8 |

||

| Example | D = Ø12 H7 L = 30 n = 3800 rpm VC = 140 Vf = 300 mm/min (R0,4) Material GG20 |

|

| Example | D = Ø 55 L = 220 n = 1389 rpm Vc = 300x0,8 (L/D>4) Vf = 120 mm/min (RO, 4 uç için) Material Al. |

|

| Example | D = Ø 30,5 L = 100 n = 2500 rpm Vc = 240 Vf = 180 mm/min (RO, 4 / ap=0,03) Material CK45 |

|